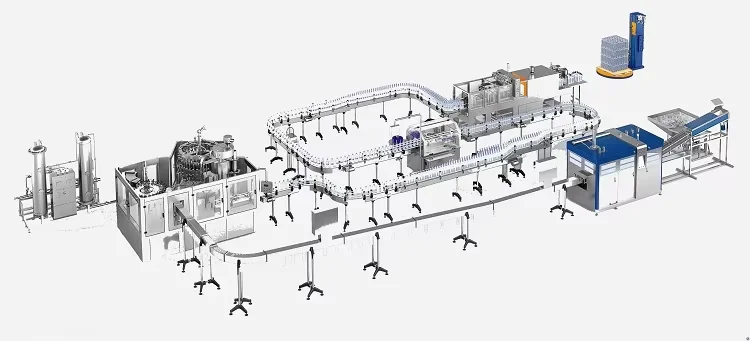

Looking for a reliable solution for your beverage packaging needs? This automatic plastic drinking water filling machine delivers exceptional performance and efficiency for both bottle and barrel filling operations. Designed with advanced technology and premium components, this production line ensures precise filling volumes and maintains strict hygiene standards throughout the process. The fully automated system handles everything from bottle rinsing to filling and capping, significantly reducing labor costs while increasing productivity. Suitable for various container sizes, this versatile machine can process both small bottles and large barrels with minimal changeover time. Built to last with durable stainless steel construction, it offers stable operation and easy maintenance. Our factory-direct pricing provides excellent value without compromising on quality, making this filling line an ideal choice for water bottling plants of all sizes.

Model |

CGF8-8-8-3/4 |

CGF12-12-5/6 |

CGF18-18-6 |

CGF24-24-8 |

||||

Application |

Spring water / mineral water / pure water / non-gas wine drink and so on |

|||||||

No. of Rinsing/Filling/Capping |

8-8-3/4 |

12-12-5/6 |

18-18-6 |

24-24-8 |

||||

Production Capacity(500ml) |

2000BPH |

4000BPH |

6000-7000BPH |

10000~12000BPH |

||||

Filling precision |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

||||

User Ambient Conditions |

Temperature:10~40℃; Humidity: No dew |

|||||||

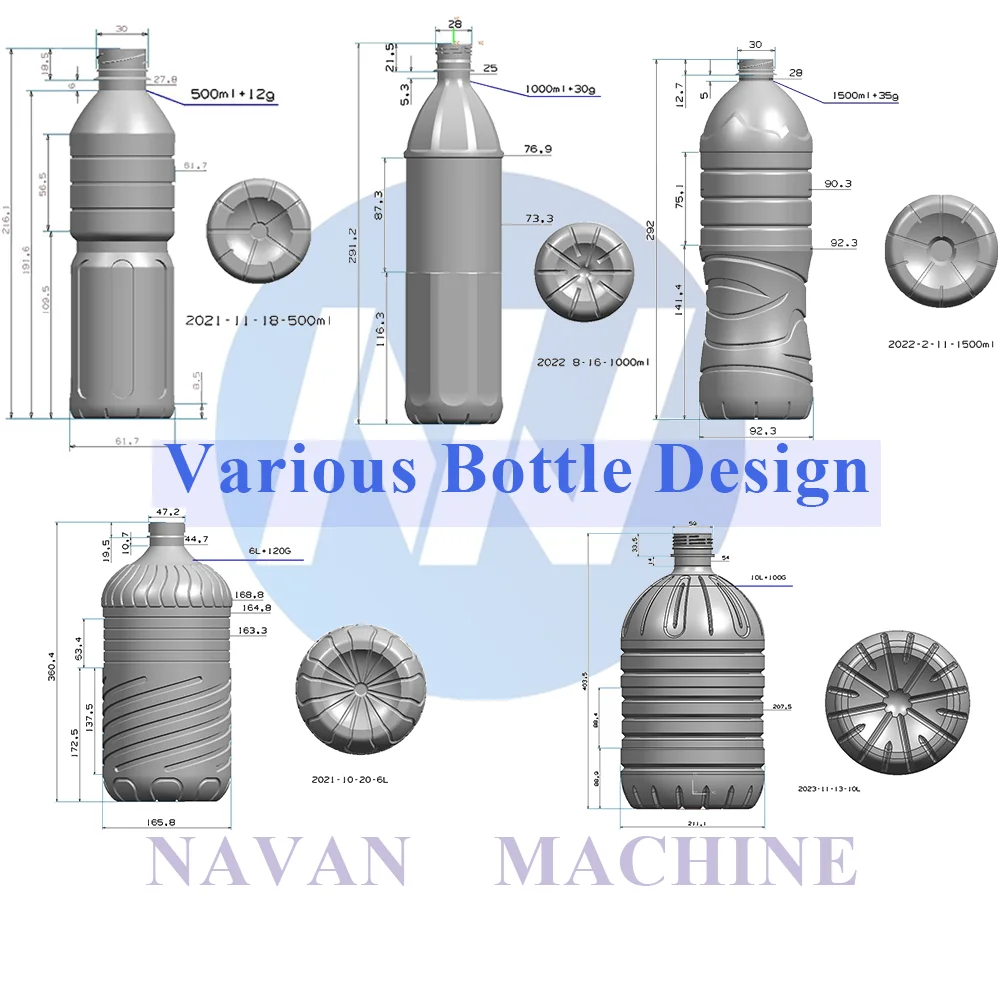

Suitable bottle specification |

Volume=100-2000ml

Diameter φ=50-100mm

Bottle height H=150 ~340mm

|

Volume=100-2000ml Diameter φ=50-105 Bottle height H=150 ~340mm |

Volume=100-2500ml

Diameter φ=50-115mm

Bottle height H=150 ~350mm

|

Volume=100-2500ml Diameter φ=50-115 Bottle height H=150 ~350mm |

||||

Bottle type |

Plastic bottle / PET Bottle |

|||||||

Bottle neck/Cap Style |

Plastic Screw Cap φ=20-50mm |

|||||||

Machine material |

Food stage SS304 OR SS316 |

|||||||

Air source pressure |

0.5~0.6Mpa |

|||||||

Filling way/principle |

Gravity filling method |

|||||||

Control system |

SIMENS PLC+ TOUCH SCREEN |

|||||||

Features |

No Bottle No Filling No Bottle No Capping |

|||||||

Main Power |

1.9kw |

3.5kw |

4.0kw |

4.8kw |

||||

Power Supply |

Voltage:220V~480V,3phase; Frequency:50HZ/60HZ or your requirement |

|||||||

Overall dimensions (mm) |

1900*1420*2000 |

2050*1800*2400 |

2580*2100*2200 |

2780*2200*2200 |

||||

Weight (kg) |

1500 |

2500 |

3500 |

4500 |

||||

All machines could be customized , we could design design and produce machines according to your request. |

||||||||

Model |

CGF32-32-10 |

CGF40-40-10/12 |

CGF50-50-12/15 |

CGF60-60-15 |

||||

Application |

Spring water / mineral water / pure water / non-gas wine drink and so on |

|||||||

No. of Rinsing/Filling/Capping |

32-32-10 |

40-40-10/12 |

50-50-12/15 |

60-60-15 |

||||

Production Capacity(500ml) |

16000-17000BPH |

19000-20000BPH |

23000-24000BPH |

34000~36000BPH |

||||

Filling precision |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

||||

User Ambient Conditions |

Temperature:10~40℃; Humidity: No dew |

|||||||

Suitable bottle specification |

Volume=100-2500ml Diameter φ=50-115mm Bottle height H=150 ~350mm |

|||||||

Bottle type |

Plastic bottle / PET Bottle |

|||||||

Bottle neck/Cap Style |

Plastic Screw Cap φ=20-50mm |

|||||||

Machine material |

Food stage SS304 OR SS316 |

|||||||

Air source pressure |

0.5~0.6Mpa |

|||||||

Filling way/principle |

Gravity filling method |

|||||||

Control system |

SIMENS PLC+ TOUCH SCREEN |

|||||||

Features |

No Bottle No Filling No Bottle No Capping |

|||||||

Main Power |

5.5kw |

7.5kw |

11.0kw |

15.0kw |

||||

Power Supply |

Voltage:220V~480V,3phase; Frequency:50HZ/60HZ or your requirement |

|||||||

Overall dimensions (mm) |

3800*2800*2600 |

4600*2800*2600 |

5450*3300*2600 |

6500*4500*2600 |

||||

Weight (kg) |

6500 |

8500 |

9800 |

12800 |

||||

All machines could be customized , we could design design and produce machines according to your request. |

||||||||