This advanced automatic water production line delivers a comprehensive solution for bottling mineral and drinking water in PET containers. Featuring state-of-the-art filling technology, the system handles everything from bottle rinsing to filling and capping with precision and efficiency. Ideal for small to medium-sized beverage manufacturers, this production line maintains strict hygiene standards while offering consistent output quality. The fully automated process minimizes human intervention, reducing labor costs and contamination risks. With adjustable speeds and bottle size compatibility, the system provides excellent flexibility for different production needs. The integrated design includes water treatment, bottle blowing, filling, labeling, and packaging modules, ensuring a seamless end-to-end bottling operation. Built with durable stainless steel construction and equipped with user-friendly controls, this water filling line combines reliability with ease of maintenance for long-term performance.

Equipment Type |

Automatic |

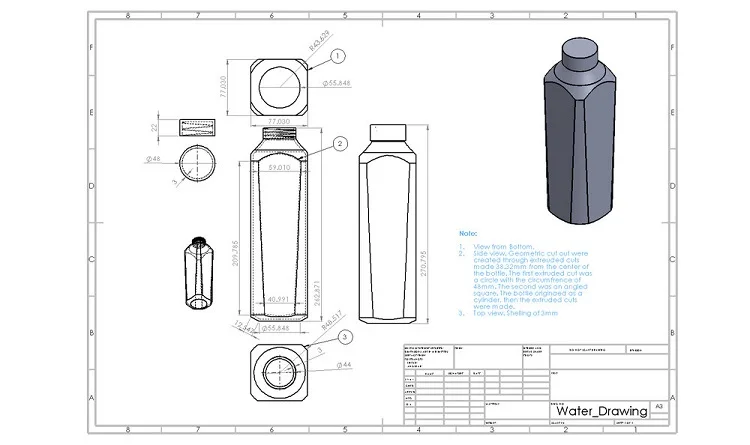

Bottle Type |

PET round or square bottle Volume 200 - 2500ml Bottle diameter 50-115mm Bottle height 160-350mm |

Output |

up to 36,000 BPH |

Your product |

mineral water/pure water/non-gas wine drink and so on. |

Model |

XGF8-8-8-4 |

XGF12-12-6 |

XGF18-18-6 |

XGF24-24-8 |

||||

Application |

Spring water / mineral water / pure water / non-gas wine drink and so on |

|||||||

No. of Rinsing/Filling/Capping |

8-8-3/4 |

12-12-5/6 |

18-18-6 |

24-24-8 |

||||

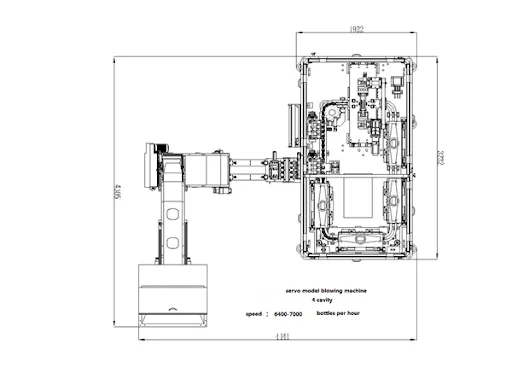

Production Capacity(500ml) |

2000BPH |

4000BPH |

6000-7000BPH |

10000~12000BPH |

||||

Filling precision |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

||||

User Ambient Conditions |

Temperature:10~40℃; Humidity: No dew |

|||||||

Suitable bottle specification |

Volume=100-2000ml

Diameter φ=50-100mm

Bottle height H=150 ~340mm

|

Volume=100-2000ml Diameter φ=50-105 Bottle height H=150 ~340mm |

Volume=100-2500ml

Diameter φ=50-115mm

Bottle height H=150 ~350mm

|

Volume=100-2500ml Diameter φ=50-115 Bottle height H=150 ~350mm |

||||

Bottle type |

Plastic bottle / PET Bottle |

|||||||

Bottle neck/Cap Style |

Plastic Screw Cap φ=20-50mm |

|||||||

Machine material |

Food stage SS304 OR SS316 |

|||||||

Air source pressure |

0.5~0.6Mpa |

|||||||

Filling way/principle |

Gravity filling method |

|||||||

Control system |

SIMENS PLC+ TOUCH SCREEN |

|||||||

Features |

No Bottle No Filling No Bottle No Capping |

|||||||

Main Power |

1.9kw |

3.5kw |

4.0kw |

4.8kw |

||||

Power Supply |

Voltage:220V~480V,3phase; Frequency:50HZ/60HZ or your requirement |

|||||||

Overall dimensions (mm) |

1900*1420*2000 |

2050*1800*2400 |

2580*2100*2200 |

2780*2200*2200 |

||||

Weight (kg) |

1500 |

2500 |

3500 |

4500 |

||||

All machines could be customized , we could design and produce machines according to your request. |

||||||||

Model |

XGF32-32-10 |

XGF40-40-12 |

XGF50-50-15 |

XGF60-60-15 |

||||

Application |

Spring water / mineral water / pure water / non-gas wine drink and so on |

|||||||

No. of Rinsing/Filling/Capping |

32-32-10 |

40-40-10/12 |

50-50-12/15 |

60-60-15 |

||||

Production Capacity(500ml) |

16000-17000BPH |

19000-20000BPH |

23000-24000BPH |

34000~36000BPH |

||||

Filling precision |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

≤±5mm(liquid level) |

||||

User Ambient Conditions |

Temperature:10~40℃; Humidity: No dew |

|||||||

Suitable bottle specification |

Volume=100-2500ml Diameter φ=50-115mm Bottle height H=150 ~350mm |

|||||||

Bottle type |

Plastic bottle / PET Bottle |

|||||||

Bottle neck/Cap Style |

Plastic Screw Cap φ=20-50mm |

|||||||

Machine material |

Food stage SS304 OR SS316 |

|||||||

Air source pressure |

0.5~0.6Mpa |

|||||||

Filling way/principle |

Gravity filling method |

|||||||

Control system |

SIMENS PLC+ TOUCH SCREEN |

|||||||

Features |

No Bottle No Filling No Bottle No Capping |

|||||||

Main Power |

5.5kw |

7.5kw |

11.0kw |

15.0kw |

||||

Power Supply |

Voltage:220V~480V,3phase; Frequency:50HZ/60HZ or your requirement |

|||||||

Overall dimensions (mm) |

3800*2800*2600 |

4600*2800*2600 |

5450*3300*2600 |

6500*4500*2600 |

||||

Weight (kg) |

6500 |

8500 |

9800 |

12800 |

||||

All machines could be customized , we could design and produce machines according to your request. |

||||||||