3.Machina butyrum lavandam, impletam et claudendam.

4.Siccator butyrum.

5.Automatica machina Alabelandi .

6.Impacetus calefactu contrahens machina Involucrati .

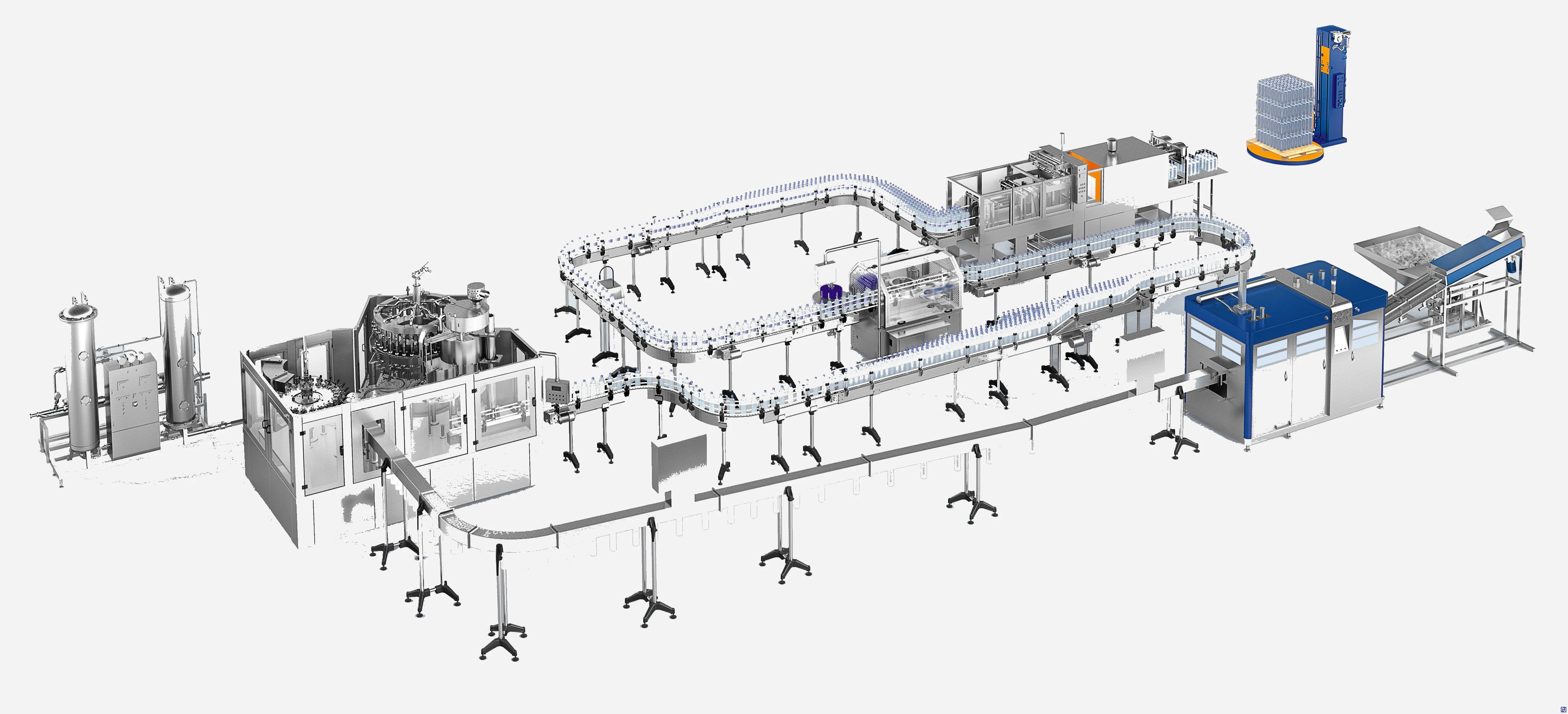

Haec planta automatistica liquidorum bottling praebet solutionem completam pro operationibus packaging aquae mineralis et purae. Confecta ad productionem altae efficientiae, systema integrat functiones filling, capping, et packaging pro plasticis butellis parvis. Mechanismus filling ingeniose fabricatus certum control voluminis et minimum effusium praestat, dum systema capping automatizatum securas sigillationes pro fresco et securitate producti confirmat. Capacitas variorum magnitudinum butellarum tractandarum, haec machina versatile constantem performance praebet cum minima interventione operatoris. Pedestris compacta facit idoneum pro facilitatibus parvis usque ad mediocribus, dum impressiones perfluxionis admirabiles servat. Aedificata ex acco inedito alimentario et praebens controles amica-user, hoc instrumentum normas hygienicas severas implent et facilem conservationem offert. Perfectum pro fabricatoribus potu, societatibus bottling aquae, et similibus industriis quaerentibus solutiones packaging automatizatas fide dignas.

Model |

CGF8-8-3/4 |

CGF12-12-5/6 |

CGF18-18-6 |

CGF24-24-8 |

||||

Applicatio |

Aqua fontana / aqua mineralis / aqua pura / potus vinarius sine gas et cetera |

|||||||

Numerus Enitionis/Implectionis/Obturationis |

8-8-3/4 |

12-12-5/6 |

18-18-6 |

24-24-8 |

||||

Capacitas Productionis (500ml) |

2000BPH |

4000BPH |

6000-7000BPH |

10000~12000BPH |

||||

Praecisio impletionis |

≤±5 mm (nivellus liquidi) |

≤±5 mm (nivellus liquidi) |

≤±5 mm (nivellus liquidi) |

≤±5 mm (nivellus liquidi) |

||||

Conditiones ambientis usoris |

Temperatura: 10–40 ℃; Humiditas: Sine rore |

|||||||

Specificatio phialae idonea |

Capacitas = 100–2000 ml

Diameter φ = 50–100 mm

Altitudo phialae H = 150–340 mm

|

Capacitas = 100–2000 ml Diameter φ = 50–105 Altitudo phialae H = 150–340 mm |

Capacitas = 100–2500 ml

Diameter φ=50-115mm

Altitudo ampullae H=150 ~350mm

|

Capacitas = 100–2500 ml Diameter φ=50-115 Altitudo ampullae H=150 ~350mm |

||||

Typus ampullae |

Ampulla plastica / PET Ampulla |

|||||||

Collum ampullae/Stilus operculi |

Opertorium plasticum a filemento φ=20-50mm |

|||||||

Materies machinae |

SS304 vel SS316 gradus cibi |

|||||||

Pressio fontis aeris |

0.5~0.6Mpa |

|||||||

Modus/principium impletionis |

Modus impletionis gravitatis |

|||||||

Systema regulandi |

SIMENS PLC+ TOUCH SCREEN |

|||||||

Peculiaritates |

Nulla ampulla, nulla impletio; nulla ampulla, nulla operculatio |

|||||||

Potentia principalis |

1.9kw |

3.5kw |

4,0kw |

4,8kw |

||||

Fontem electricitatis |

Tensio: 220V~480V, tribus fasis; Frequencia: 50Hz/60Hz vel iuxta petitionem tuam |

|||||||

Dimensiones generales (mm) |

1900*1420*2000 |

2050*1800*2400 |

2580*2100*2200 |

2780*2200*2200 |

||||

Pondus (kg) |

1500 |

2500 |

3500 |

4500 |

||||

Omnes machinae possunt accommodari; possumus machinas pro te designare et producere iuxta petitionem tuam. |

||||||||