This versatile 3-in-1 rotary filling machine is specifically engineered for efficient olive oil packaging operations. The automatic system seamlessly combines filling, capping, and labeling functions in one compact unit, maximizing production efficiency while minimizing floor space. Featuring precision-controlled filling heads, the machine ensures accurate volumetric dispensing to prevent waste and maintain consistent fill levels. Its hygienic stainless steel construction meets food-grade standards and allows for easy cleaning and maintenance. Capable of handling various bottle sizes and shapes, this filling line achieves speeds of up to 40-60 bottles per minute depending on container specifications. The user-friendly PLC control system enables quick parameter adjustments and supports multiple filling programs. Perfect for olive oil producers, bottling facilities, and food processing plants seeking to streamline their packaging operations while maintaining product quality.

Equipment model |

YGF(W)16-5 type |

||||||||

Number of stations: |

16 for filling, 5 for capping |

||||||||

Rated production capacity: |

3000 bottles/hour (1000ml/bottle) |

||||||||

Compressed air pressure: |

0.7MPa, air consumption: 0.3m3/min |

||||||||

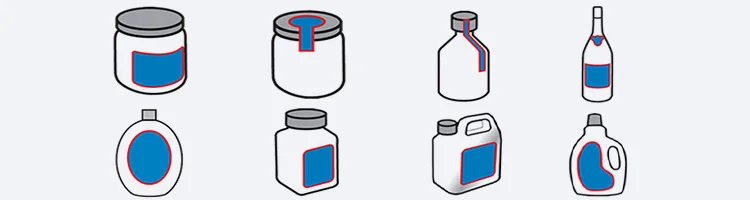

Adapt to bottle type: |

diameter Φ50~Φ100, bottle height 150~350 |

||||||||

Main motor power: |

2.2KW |

4-6pcs |

8-10 pcs |

12pcs |

|||||

Dimensions: |

2200×2000×2700 mm(L×W×H) |

||||||||

Equipment weight: |

3000Kg |

600-800BPH |

1800-2500BPH |

3000-3500BPH |

|||||