Air bubbles and product waste represent two of the most significant challenges facing modern jam manufacturers during the filling process. These issues not only compromise product quality and visual appeal but also result in substantial financial losses through reduced yield and increased material costs. Understanding the root causes of these problems and implementing effective prevention strategies is crucial for maintaining competitive advantage in today's demanding food processing industry. The key to success lies in selecting appropriate equipment, optimizing process parameters, and establishing comprehensive quality control protocols that address both technical and operational aspects of jam production.

Understanding the Science Behind Air Bubble Formation

Physical Properties of Jam and Viscosity Factors

The formation of air bubbles in jam during filling processes is directly related to the product's viscosity and flow characteristics. High-viscosity jams tend to trap air more readily than thinner products, creating pockets of gas that become visible in the final packaged product. The pectin content, sugar concentration, and fruit particle distribution all influence how air becomes incorporated during the filling process. Temperature variations also play a critical role, as heated jam exhibits different flow properties compared to room temperature product, affecting bubble formation rates and patterns.

Understanding these physical properties allows manufacturers to adjust filling parameters accordingly. The Reynolds number, which describes fluid flow patterns, becomes particularly important when dealing with non-Newtonian fluids like jam. Laminar flow conditions generally produce fewer air bubbles compared to turbulent flow, making flow velocity control essential for quality outcomes. Additionally, the thixotropic nature of many jam formulations means that shear forces during filling can temporarily reduce viscosity, potentially improving flow characteristics while simultaneously creating opportunities for air entrainment.

Pressure Dynamics and Flow Rate Considerations

Pressure differentials within filling systems significantly impact air bubble formation and waste generation. When filling pressure exceeds optimal levels, turbulent flow conditions develop, increasing the likelihood of air entrainment and creating inconsistent fill volumes. Conversely, insufficient pressure can lead to incomplete fills, dripping, and extended cycle times that reduce overall production efficiency. Modern jam filling machine systems incorporate pressure monitoring and control mechanisms that maintain optimal conditions throughout the filling cycle, ensuring consistent product quality and minimizing waste generation.

Flow rate optimization requires careful balance between production speed and quality outcomes. Higher flow rates generally increase productivity but may compromise fill accuracy and bubble formation control. Advanced filling systems utilize variable speed controls and servo-driven mechanisms that can adjust flow rates in real-time based on product characteristics and container specifications. This dynamic approach allows manufacturers to maintain high production rates while preserving product quality standards and minimizing material waste.

Equipment Selection and Configuration Strategies

Filling Valve Technology and Design Considerations

The selection of appropriate filling valve technology represents a critical decision point for jam manufacturers seeking to minimize air bubbles and waste. Positive displacement valves offer superior accuracy and control compared to gravity-fed systems, particularly when handling viscous products with varying flow characteristics. These valves can maintain consistent fill volumes regardless of product viscosity fluctuations, reducing both overfill waste and underfill quality issues. Additionally, specialized valve designs incorporate air evacuation features that actively remove trapped gases before and during the filling process.

Bottom-up filling techniques have proven particularly effective for jam applications, as they minimize air entrainment by allowing product to flow smoothly into containers without creating turbulence at the surface. This approach requires careful coordination between valve positioning, container handling, and fill sequence timing to achieve optimal results. Anti-drip mechanisms integrated into modern valve designs prevent product waste between fills while maintaining sanitary conditions throughout the production process.

Container Handling and Positioning Systems

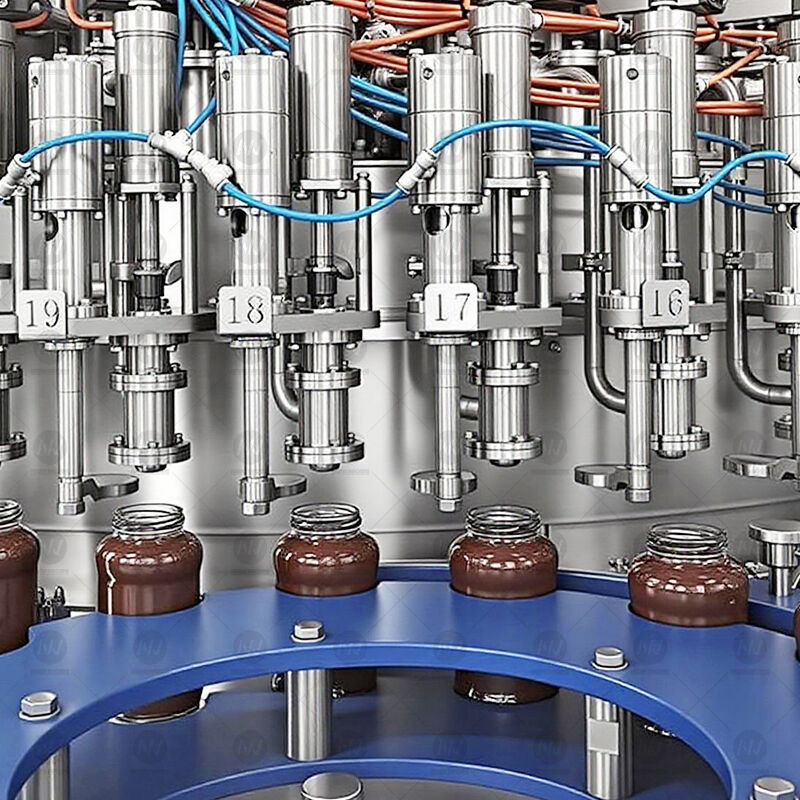

Precise container positioning during the filling process directly impacts both air bubble formation and waste generation. Misaligned containers can cause product spillage, cross-contamination, and incomplete fills that require costly rework or disposal. Advanced positioning systems utilize servo-controlled mechanisms and vision-guided alignment to ensure consistent container placement with minimal human intervention. These systems can accommodate various container sizes and shapes while maintaining the precise positioning required for optimal filling performance.

Vibration control during filling operations helps prevent air bubble migration and settlement issues that can affect final product appearance. Controlled vibration can actually assist in bubble removal when applied correctly, but excessive or uncontrolled movement can worsen bubble formation and create filling accuracy problems. Modern filling systems incorporate programmable vibration control that can be adjusted based on product characteristics and container specifications to optimize bubble removal while maintaining filling precision.

Process Optimization and Parameter Control

Temperature Management Throughout the Filling Process

Maintaining optimal temperature control throughout the filling process is essential for minimizing both air bubble formation and product waste. Jam products typically exhibit temperature-dependent viscosity characteristics, with higher temperatures generally reducing viscosity and improving flow properties. However, excessive heat can degrade product quality, alter flavor profiles, and create safety concerns for equipment operators. Establishing precise temperature control protocols ensures consistent product flow while preserving quality attributes and maintaining safe operating conditions.

Temperature uniformity within the product supply system prevents localized viscosity variations that can lead to inconsistent filling performance. Hot spots or cold zones within holding tanks or transfer lines can create flow irregularities that manifest as filling volume variations and increased waste generation. Implementing comprehensive temperature monitoring and control systems throughout the product path ensures uniform conditions and predictable filling performance across all production runs.

Vacuum Integration and Degassing Techniques

Vacuum-assisted filling techniques offer significant advantages for jam applications by actively removing air from both the product and the filling environment. Pre-filling vacuum treatment can extract dissolved gases from jam products before they enter the filling system, reducing the potential for bubble formation during the actual filling process. This approach requires careful integration with existing production equipment and may necessitate modifications to product handling systems to maintain vacuum conditions throughout the filling cycle.

Degassing chambers positioned upstream of filling stations provide additional opportunities for air removal while allowing continuous production flow. These systems utilize controlled vacuum levels and residence times to extract trapped gases without affecting product quality or consistency. The effectiveness of degassing operations depends on proper sizing, vacuum level control, and integration with downstream filling equipment to prevent air re-entrainment during product transfer.

Quality Control Measures and Monitoring Systems

Real-Time Fill Volume Verification

Implementing comprehensive fill volume monitoring systems enables immediate detection and correction of filling irregularities that contribute to waste generation. Modern checkweighing systems can identify overfill and underfill conditions in real-time, allowing for immediate process adjustments that minimize product loss and maintain quality standards. These systems typically incorporate statistical process control capabilities that track filling performance trends and provide early warning of developing problems before they impact production efficiency.

Vision-based inspection systems offer additional capabilities for detecting air bubbles and other quality defects in filled containers. These systems can identify bubble presence, size, and distribution patterns while simultaneously verifying fill levels and product appearance. Integration with filling system controls enables automatic rejection of defective products while providing data feedback for process optimization and continuous improvement initiatives.

Preventive Maintenance and System Calibration

Regular maintenance and calibration of jam filling machine components ensures consistent performance and minimizes the risk of unexpected quality issues. Filling valve wear, seal degradation, and calibration drift can all contribute to increased air bubble formation and filling accuracy problems. Establishing comprehensive maintenance schedules based on equipment manufacturer recommendations and production volume requirements helps prevent quality issues while maximizing equipment reliability and productivity.

Documentation and tracking of maintenance activities provide valuable insights into equipment performance patterns and help identify opportunities for process improvements. Regular calibration verification using certified reference standards ensures that filling accuracy remains within acceptable tolerances and helps maintain compliance with regulatory requirements and quality standards.

Advanced Technologies and Innovation Opportunities

Servo-Controlled Filling Systems

Servo-driven filling technologies offer unprecedented precision and control capabilities that can significantly reduce both air bubble formation and product waste. These systems provide programmable fill profiles that can be customized for specific jam formulations and container requirements, optimizing flow characteristics throughout the filling cycle. Variable speed control during different phases of filling allows for gentle initial flow to minimize air entrainment followed by higher speeds to complete fills efficiently.

Integration with advanced process monitoring systems enables servo-controlled fillers to make real-time adjustments based on product characteristics and environmental conditions. This adaptive capability helps maintain consistent quality outcomes even when dealing with natural variations in jam products or changing production conditions. The precision offered by servo technology also enables more accurate portion control, reducing giveaway while ensuring compliance with regulatory fill requirements.

Smart Manufacturing Integration

Industry 4.0 technologies are transforming jam filling operations by providing unprecedented visibility into process performance and quality outcomes. IoT-enabled sensors throughout filling systems collect continuous data on pressure, temperature, flow rates, and fill volumes, enabling comprehensive process monitoring and optimization. Machine learning algorithms can analyze this data to identify patterns and predict potential quality issues before they occur, allowing for proactive adjustments that prevent waste and maintain product quality.

Predictive maintenance capabilities enabled by smart manufacturing technologies help prevent equipment failures that could lead to quality problems and production disruptions. By monitoring equipment performance indicators and comparing them to historical baselines, these systems can identify developing issues and schedule maintenance activities to minimize impact on production schedules while ensuring optimal equipment performance.

FAQ

What causes air bubbles to form in jam during the filling process

Air bubbles in jam typically form due to turbulent flow conditions during filling, rapid product movement that creates cavitation effects, or improper valve design that allows air entrainment. High viscosity products like jam are particularly susceptible to bubble formation when filling parameters are not optimized for their specific flow characteristics. Temperature variations, excessive filling pressure, and inadequate degassing can also contribute to bubble formation problems.

How can filling speed affect both air bubble formation and waste generation

Excessive filling speeds often create turbulent flow conditions that increase air entrainment and bubble formation while also reducing filling accuracy and increasing waste through overfill or spillage. However, extremely slow filling speeds can lead to dripping, extended cycle times, and temperature-related quality issues. The optimal filling speed balances production efficiency with quality requirements, typically achieved through variable speed control that adjusts flow rates during different phases of the filling cycle.

What role does container design play in preventing air bubbles and waste

Container design significantly impacts filling performance, with narrow neck openings potentially creating backpressure and turbulence that promotes bubble formation. Wide mouth containers generally fill more easily but may require different filling techniques to prevent splashing and waste. Container material properties, internal surface finish, and geometric features all influence how jam flows during filling and whether air becomes trapped in the final product.

How often should jam filling equipment be calibrated to maintain optimal performance

Filling equipment calibration frequency depends on production volume, product characteristics, and equipment design, but most manufacturers perform daily verification checks with more comprehensive calibrations weekly or monthly. High-volume operations may require more frequent calibration to maintain accuracy, while facilities processing products with varying viscosities may need calibration adjustments between product changeovers. Regular calibration ensures consistent fill accuracy and helps prevent both underfill waste and overfill giveaway issues.