Understanding Modern Industrial Jam Processing Equipment

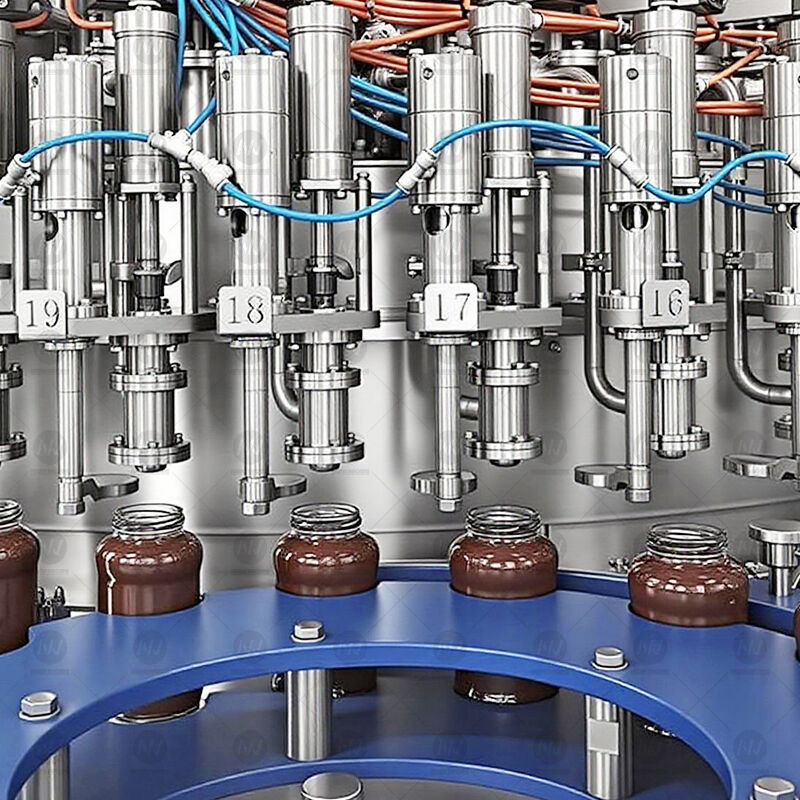

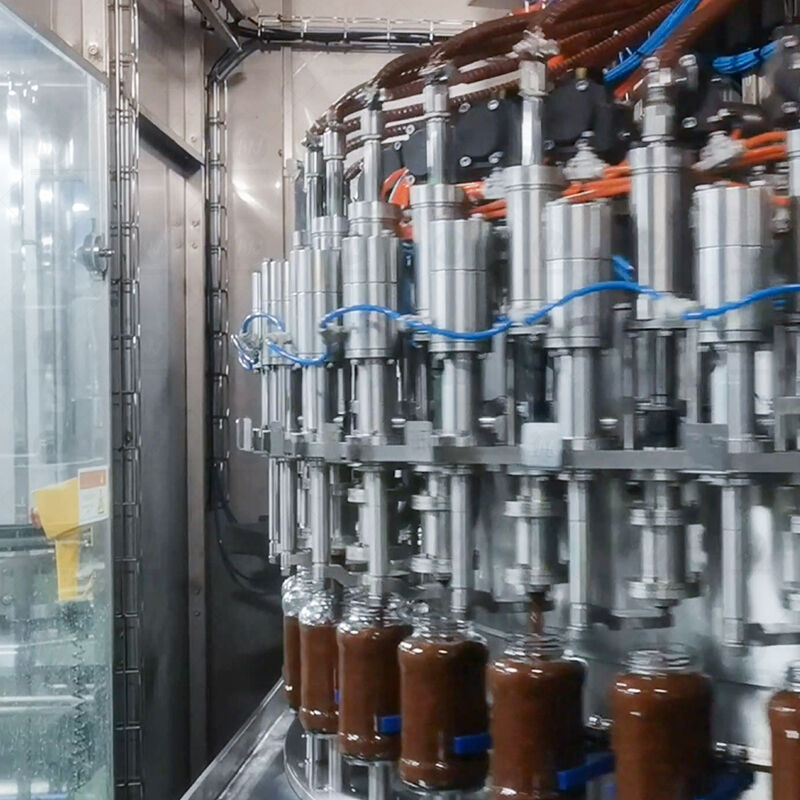

The food processing industry has witnessed remarkable technological advancements, particularly in the realm of handling viscous products. At the heart of efficient jam production lies the sophisticated jam filling machine, a crucial piece of equipment designed to handle thick, sticky substances with precision and consistency. These machines have revolutionized the way manufacturers process and package jams, preserves, and similar products, ensuring both quality and productivity in modern food processing facilities.

Today's jam filling machines incorporate advanced features that overcome the traditional challenges of handling sticky substances. From precise temperature control to specialized nozzle designs, these machines represent the pinnacle of food processing technology. Understanding their operation and capabilities is essential for manufacturers looking to optimize their production lines and maintain competitive advantage in the market.

Core Components and Technical Features

Advanced Pumping Systems

The heart of any jam filling machine is its pumping mechanism. Modern units utilize positive displacement pumps, specifically designed to handle high-viscosity products. These pumps maintain consistent pressure and flow rates, ensuring uniform filling across all containers. The pumping system often incorporates progressive cavity or lobe pump designs, which are particularly effective at moving thick products without damaging their texture or incorporating unwanted air.

Temperature-controlled hoppers and transfer lines complement the pumping system, maintaining optimal product viscosity throughout the filling process. This precise temperature control prevents the jam from becoming too thick or thin, ensuring consistent flow and accurate filling volumes.

Precision Nozzle Technology

The nozzle design plays a critical role in handling sticky products. Advanced jam filling machines feature anti-drip nozzles with cut-off mechanisms that prevent product stringing and ensure clean fills. These nozzles are often heated to maintain proper product flow and are constructed from materials that resist product adherence, such as specialized food-grade stainless steel or non-stick coatings.

Modern nozzles also incorporate adjustable parameters for different product consistencies, allowing operators to fine-tune the filling process for various jam types and container sizes. This flexibility ensures optimal performance across a wide range of products.

Process Control and Automation Features

Intelligent Control Systems

Modern jam filling machines utilize sophisticated PLC (Programmable Logic Controller) systems that monitor and adjust various parameters in real-time. These systems control filling volumes, speeds, and timing with exceptional precision. The automation extends to temperature regulation, pressure control, and flow rate adjustment, ensuring consistent product quality throughout extended production runs.

Advanced sensors throughout the system provide continuous feedback, allowing the machine to make automatic adjustments when variations are detected. This level of control is essential for maintaining precise fill levels and preventing issues like overflow or underfilling.

Clean-in-Place Capabilities

Handling sticky products necessitates robust cleaning systems. State-of-the-art jam filling machines feature comprehensive Clean-in-Place (CIP) systems that automatically clean and sanitize all product contact surfaces. These systems use specialized cleaning solutions and precise timing sequences to ensure thorough cleaning without manual intervention.

The CIP systems are designed to reach all critical areas, including pipes, pumps, and filling nozzles, ensuring complete removal of product residue and maintaining hygiene standards. This automation significantly reduces downtime between production runs and ensures consistent product quality.

Production Efficiency and Output Optimization

Speed and Volume Management

Modern jam filling machines achieve impressive production rates while maintaining accuracy. Advanced systems can handle multiple containers simultaneously, with filling speeds often reaching several hundred units per minute. The machines accomplish this while maintaining fill accuracy typically within ±0.5% of the target volume.

Variable speed drives and intelligent product flow management systems allow for smooth acceleration and deceleration, preventing product splash or waste during container transitions. This precise control enables manufacturers to maximize throughput while maintaining product quality.

Waste Reduction Technologies

Efficient handling of thick products requires sophisticated waste reduction features. Modern jam filling machines incorporate product recovery systems that minimize waste during product changeovers and end-of-run situations. These systems often include specialized algorithms that calculate optimal filling parameters to reduce overflow and underfilling.

Advanced machines also feature product recirculation systems that maintain proper temperature and consistency during temporary line stoppages, preventing product degradation and waste. This attention to waste reduction contributes significantly to operational efficiency and cost savings.

Maintenance and Performance Optimization

Preventive Maintenance Systems

To ensure consistent performance when handling sticky products, jam filling machines incorporate sophisticated maintenance monitoring systems. These systems track operating hours, cycle counts, and wear patterns, alerting operators when maintenance is required. Predictive maintenance algorithms can even forecast potential issues before they cause production disruptions.

Quick-change components and tool-less maintenance access points facilitate rapid cleaning and parts replacement, minimizing downtime. This design philosophy ensures that routine maintenance can be performed efficiently without compromising production schedules.

Performance Analytics and Reporting

Modern jam filling machines include comprehensive data collection and analysis capabilities. These systems track key performance indicators such as filling accuracy, speed, and downtime, providing valuable insights for process optimization. Real-time monitoring allows operators to identify and address efficiency issues promptly.

Advanced reporting features generate detailed production reports, compliance documentation, and maintenance records, supporting quality control and regulatory requirements. This data-driven approach enables continuous improvement in operational efficiency.

Frequently Asked Questions

What fill accuracy can be expected from a modern jam filling machine?

Modern jam filling machines typically achieve fill accuracy within ±0.5% of the target volume, thanks to advanced control systems and precise nozzle technology. This high level of accuracy is maintained even at high production speeds and with varying product consistencies.

How do jam filling machines maintain product consistency throughout long production runs?

These machines utilize temperature-controlled hoppers and transfer lines, combined with sophisticated pumping systems and real-time monitoring. The integrated control systems continuously adjust parameters to maintain optimal product flow and consistency, ensuring uniform filling throughout the production process.

What cleaning procedures are necessary for jam filling machines?

Modern jam filling machines feature automated Clean-in-Place (CIP) systems that handle most cleaning requirements. These systems use programmed cleaning cycles with specialized solutions to clean all product contact surfaces. Regular maintenance cleaning and periodic deep cleaning schedules should be followed according to manufacturer specifications and production requirements.

How do jam filling machines handle different product viscosities?

Advanced jam filling machines offer adjustable parameters for pump speeds, nozzle settings, and temperature control. These adjustments allow operators to optimize the machine's performance for different product viscosities, ensuring efficient handling of various jam formulations and consistencies.